It is very important to do the maintenance well ,so that could keep Gerson traveling head press with good performance and service life.The following is most for the manual traveling head press or traveling head cutting machine.

1.The oil pipe joint shouldve locked,without any oil leakage.In addition,the oil pipe could not rub against with other goods,so as to avoid any breakage.

2.Check the tension of the chain once every month,and tur the adjusting screw by torque wrench.

3.Lubricate the guid rod monthly .Clean the guide rail and add the lubricant each month.

4.Replace the lubricant of the reducation device every 6000 working hours.(The lubr9cant performance is equal to EP460 (Kg.4.400)

5.The hydraulic oil of the oil tank should be replaced and the filter net should clean off every 8000 hours ,or when the noise of the oil pump begains bigger and bigger.

It is advised to use MOBILE DET 35 or SHELL TELLUS 46 or the hydraulic oil eqyuvalent to ISO VG 46.

The oil tank and the filter net should be completed cleaned when replacing the hydraulic oil.The oil level should be higner than the filter net and full of the oil tank adding the lubricant.

6.The traveling head press is required to keep the electrical accessories clean.

The press is strictly forbidden to haave oil or other flammable things sticking on the electrical components.it is also not allowed to cover ,pack the electrical components or the electrical instrument box by the flammable things,so as to avoid fire.

7.The machine is required to clean the machine and check the screw every day.

8.The machine is required to turn the cutting plate or cutting board over to use every week.

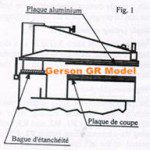

9.The machine is required to turn the aluminum plate and change the direction every 3 months so as to decrease the wear and tear.

10.Please turn off the motor as much as possible if the machine does not work.