Roller Die Cutter Press

Manufacturer & Supplier

38+ Years

Superior Performance with High Quality

Custom Design Based on Request

Full Support on Installstion&Traning

Roller Die Cutter Press Leading Manufacturer

With a legacy spanning 38 years, Gerson is a leading manufacturer of cutting-edge roller die cutting presses. Our GRDC machines deliver unparalleled accuracy and consistency, offering flexibility, reliability, and superior cutting performance.

Leverage our deep industry knowledge to address your specific die cutting challenges. From state-of-the-art machinery to precision tooling, Gerson offers comprehensive solutions tailored to your exact requirements.Our team of seasoned professionals is dedicated to providing exceptional customer service and support.

Gerson is your one-stop solution for all your die cutting needs. Contact us today to learn more about our equipment and tooling.

Roller Die Cutter Features & Specification

GRDC Main Features

Gerson GRDC boasts several key features that enhance its functionality and usability. Below is a detailed breakdown of these features, followed by a summary table for clarity.

1. Silent Operation:The GRDC operates quietly, ensuring minimal noise disruption during use. This feature makes it suitable for environments where noise levels must be kept low. Additionally, the machine is designed for safe and simple operation, which means that even beginners can use it without extensive training or adjustments.

2. High Hardness Solid Alloy Shaft:The device is equipped with a high hardness solid alloy shaft that is resistant to wear and tear. This shaft undergoes high-frequency cylindrical grinding, which enhances its hardness and ensures high concentricity. This precision contributes to the overall performance and longevity of the machine.

3. Durable Stainless Steel Table Surface:The table surface of the GRDC is made from high hardness stainless steel, providing excellent resistance against scratches and rust. This durability ensures that the surface remains clean and functional over long periods of use, making maintenance easier for operators.

4. Heavy-Duty Bearing System:The equipment utilizes heavy-duty parts featuring German BKD double bearings at each stress point. This design allows the machine to operate smoothly over extended periods without requiring special maintenance, thereby reducing downtime and increasing productivity.

5. Advanced Electric Control System:The GRDC includes an electric control system with a frequency converter for speed control. It features automatic counting capabilities and a two-way switch for operation flexibility. Users can choose between two-way automatic shutdown or manual shutdown options, along with one-key switching for ease of use.

6. Versatile Functionality:This machine can perform various tasks including cut-through operations, half-through processes, compression line forming, and handling high-frequency hardened gears as well as 12.9 grade alloy screws. Its versatility makes it suitable for a wide range of applications in different industries.

7. Sturdy Frame Construction:Constructed from 120 square tubes, the frame provides enhanced stability due to its design that supports weight distribution across all four sides. The option to equip the machine with four heavy-duty casters facilitates easy movement within workspaces.

8.Thickened Casing Design:The GRDC features a thickened casing that enhances durability while also allowing both sides of the feeding table to be disassembled and folded easily. This design facilitates convenient logistics packaging and shipping, making it easier to transport the machine upstairs or into elevators.

GRDC Main Specification

| Model | GERSON GRDC |

| Max Cutting Force(T) | From 10 Tons to 200 Tons |

| Distance between Shafts: | 0 – 100 mm |

| Speed | 6-8 cycles/min |

| Cutting area(mm) | (200-3000)X(300-3000)mm |

| Based on your material and die | |

| Example: 1600X600mm etc., | |

| Shafts diameter: | 200mm-350 mm |

| Electric Power | 220V/380V/415V,50-60hz etc., |

| Motor power | 0.75Kw to 22KW |

Roller Die Cutter Aplication

Material in Application

Top quality roller die cutter press machines are ideal for die-cutting a wide range of soft and semi-rigid materials, including:

Cardboard:Corrugated Board,Corrugated fiberboard or Combined board ,Hard Paper,Corrugated Fiberboard Carton .Single , Double and Triple Wall Packaging .

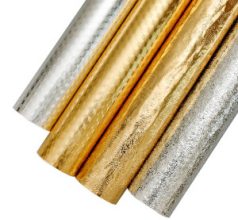

Foil (Metal foils):Aluminum foil,Copper Foil, Gold Foil , Silver Foil, Tin Foil,Stainless Steel Foil or Holographic Foils,Pigmented Foils etc.,.

Fabric : including Semi-synthetic Fabric, Synthetic Fabric, Woven Fabric ,Non-woven Fabric etc., Cotton,Silk,Polyester,Wool,Linen,Denim,Canvas,Cashmere,Chenille,Chiffon,Damask,Georgette,Gingham,Modal,Muslin,Organza,Polyester,Satin,Suede,Toile,Twill,Velvet etc.,

Leather: including Artificial Leather(Synthetic leather, also known as faux leather or vegan leather),PVC Leather and PU Leather . Genuine Leather including Top Grain, Full Grain, Split Leather, Bonded Leather,Bicast,Aniline, Semi-aniline, Brush-colored leather ,Cattle Leather ,Horse Leather ,Pig leather ,Sheep Leather etc.,

Plastic:Thermoplastics including polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC). ,Polyethylene Terephthalate (PET, PETE, PETG, or PET-G),High-Density Polyethylene (HDPE), Polystyrene (PS) ,Thermoformed films,Biodegradable plastic etc.,

Foam: Polyurethane Foam,Latex Foam,Memory Foam ,Open Cell Foam,Closed Cell Foam,Gel Foam,Convoluted Foam,Charcoal foam,Acoustic foam,Aquatic filter foam etc.,

Rubber:Ethylene Propylene Diene Monomer (EPDM),Chloroprene Rubber (CR), Silicone Rubber (SiR),Specialty Rubbers,,Nitrile Butadiene Rubber (NBR): ,Fluoroelastomer Rubber ,Synthetic Rubber etc.,

The working table can custom built based on request.

Industies in Application

Packaging Industry:

Plastic Vacuum Packing ,Clamshell Packaging:Blister pack including :full seal, partial seal, trap pack (trapped blister), or mock clamshell etc.,Foam Insert :Polyethylene Foams,Cross-linked polyethylene foam (XLPE),Polyurethane Foams etc.,Corrugated Cardboard:shipping boxes, mailer boxes, and product packaging boxes.Metal Foil : Used in Food industy etc.,

Shoes &Garment Industy:

Shoes Upper :Leather shoes ,sports shoes upper part production .Shoes insoles:Foam shoes insole ,fabric shoes insoles etc.,Garment Accessory: Foam shoulder pad ,Fabric pocket,pouch,Collar etc.,

Toy Industy:

Jigsaw Puzzles :Cardboard puzzles small size from one to 3000pcs puzzles .Plush Toy :Different kinds of stuffed animals using Cotton plush,Fleece plushies,Felt plushies,Faux suede fabric,Polyester plush etc.,

Other Industies:

Used in Food,Medical , pharmaceutical, Electronics, Consumer goods, Aerospace, automotive, Textile,clothing, Agricultural.

Roller Die Cutter Video

Related Products with Roller Die Cutter

Traveling Head Press is is one of die cutting presses which can be cutting sheet or roll materlal .Gerson have manual feed type and CNC automatic feed with continuous cutting for large production output.

Beam Press is one of die cutting presses which can be cutting with large cutting die tools.If you need large volume production capacity,this model can be your good choice.More information ,clicker to see details.

Hydraulic Press

Hydrauic Press is a large type die cutting press which used in many industries.Gerson have different models of hydraulic presses for your choice.OEM or Only one can be accepted.

Roller Die Cutter : Definitive Buying Guide(keep updating: Updated on Nov 10th, 2024.)

Roller Die Cutter: Definitive Buying Guide

What is a Roller Die Cutter?

A roller die cutter, also known as a roller die cutting press or flatbed die cutting press, is a versatile machine ideal for short-run die-cutting projects. This type of press utilizes a combination of a hardened roller and a flatbed surface to precisely cut various soft and semi-rigid materials into specific shapes and patterns by the cutting die including steel rule die.

Conclusion:

- Precision Cutting: The combination of the roller and flatbed ensures clean and accurate cuts.

- Versatility: It can handle a wide range of materials and thicknesses.

- Efficiency: Ideal for short-run production, making it cost-effective for smaller quantities.

- Compatibility with Steel Rule Dies: It works effectively with steel rule dies, a popular and affordable option for custom shapes.

Roller die cutter presses are commonly used in various industries, such as packaging, printing, labeling, and manufacturing.

Why Do You Need a Roller Die Cutter?

The Gerson roller die cutter is an essential tool for efficiently cutting shapes or patterns from both small and large sheets of material. This machine not only saves time but also enhances productivity, enabling you to manufacture the products you require with greater precision.

Advantages Over Hand Cutting

If you are currently using hand cutting methods, we strongly recommend transitioning to our roller die cutter. Hand cutting can be highly impractical and often results in inconsistent shapes and wasted materials. The Gerson roller die cutter streamlines the cutting process, ensuring accuracy and efficiency that manual methods simply cannot achieve.

- Precision Cutting: Ensures accurate and clean cuts for intricate designs.

- High Efficiency: Optimizes production processes for maximum output.

- Versatility: Handles a wide range of materials and thicknesses.

- Cost-Effective: Reduces labor costs and material waste.

- Customization: Adaptable to diverse applications and specific needs.

- Quick Setup: Minimizes downtime and maximizes productivity.

- Improved Safety: Prioritizes operator safety with advanced features.

- Quality Control: Ensures consistent product quality and accuracy.

- Automation Integration: Seamlessly integrates into automated workflows.

| Benefit | Description |

|---|---|

| Precision Cutting | Ensures accurate and clean cuts for intricate designs. |

| High Efficiency | Optimizes production processes for maximum output. |

| Versatility | Handles a wide range of materials and thicknesses. |

| Cost-Effective | Reduces labor costs and material waste. |

| Customization | Adaptable to diverse applications and specific needs. |

| Quick Setup | Minimizes downtime and maximizes productivity. |

| Improved Safety | Prioritizes operator safety with advanced features. |

| Quality Control | Ensures consistent product quality and accuracy. |

| Automation Integration | Seamlessly integrates into automated workflows. |

In summary, a roller die cutter is needed for its precision cutting capabilities, high production efficiency, versatility in handling various materials, cost-effectiveness through automation, customization options for diverse applications, reduced setup times for quick changes in production runs, improved safety features for operator protection, enhanced quality control measures ensuring product consistency, and seamless integration into automated workflows.

Do I Need a Cutting Die for Roller Die Cutter Machine?

Yes.You need a cutting die .The cutting die, also known as a mold, is a metal template designed to create specific shapes and patterns in a material. This ensures consistent cuts throughout your production run, similar to how molds shape other materials in industrial processes.

While a roller die cutter press provides exceptional precision and efficiency, it relies on a companion tool to achieve its full potential: the cutting die.

Gerson can build any kinds of dies together with the press . Not only do offer high-quality roller die cutter presses, but we can also design and build custom cutting dies specific to your needs. This eliminates the hassle of sourcing dies elsewhere and guarantees compatibility with your press.

What Kinds of Cutting Die for Gerson Roller Die Cutter Press?

Gerson roller die cutter press can be suitable for any common cutting die ,such as steel rule die ,forged die etc.,.

The steel rule die have a wooden or aluminum or acrylic base on the bottom of the die to hold the die.So that you can put or on the material.

Steel Rule Dies:

Steel rule dies are the most widely used type of die for roller die cutters. They offer a good balance of cost, durability, and flexibility for various applications. Here’s a breakdown of their key components:

- Cutting Rule: This is the thin, sharp metal blade that creates the desired shape in the material. It can be made from various steel alloys depending on the specific cutting requirements.

- Base: The base provides a sturdy foundation for the cutting rule. It’s typically made from wood, aluminum, or acrylic, depending on factors like the die size, cutting pressure, and cost considerations.

- Wooden bases: Offer a cost-effective option but may require more frequent replacement due to wear and tear.

- Aluminum bases: Provide a more durable alternative to wood and can handle higher cutting pressures.

- Acrylic bases: Offer excellent visibility for intricate die designs but might not be suitable for heavy-duty applications.

Forged Dies: They are created by shaping steel into the desired cutting shape through a forging process. This process results in a strong and precise cutting edge that can handle heavy-duty materials and withstand frequent use.

Forged dies offer several advantages:

- Durability: Their robust construction allows for extended use and frequent sharpening.

- Precision: The forging process ensures accurate and consistent cuts.

- Versatility: They can be used for a wide range of materials, including thick and dense materials.

However, forged dies are generally more expensive than steel rule dies, and they may require more specialized machinery for their production.

Any other dies can be used for Gerson roller die cutter press. If you have own dies ,but you cannot make sure if it is suitable or not ,you can contact us for making sure.If you do not have a die ,we could build any kinds or custom cutting die for you.

What's The Difference Between Roller Die Cutter and Rotary Die Cutting Machine ?

Both roller die cutters and rotary die cutters are valuable tools in the die-cutting industry, each with its own strengths and weaknesses. While they both serve the purpose of cutting materials, they operate differently and are suited for different applications.

Roller die cutter:

A roller die cutter is a type of flatbed die cutter. It uses a roller to apply pressure to the cutting die and material, but the cutting itself is done by the flat die, often a steel rule die.Here’s a more detailed explanation:

- Flatbed Design: The machine has a flatbed where the material is placed.

- Roller Mechanism: A roller is used to apply pressure to the material, ensuring a clean and accurate cut.

- Cutting Die: Typically uses steel rule dies, which are flat and can be customized for various shapes and sizes.

- Material Handling: Suitable for sheet materials.

- Production Speed: While faster than manual cutting methods, it’s generally slower than rotary die cutters.

- Applications: Ideal for short-run production, prototyping, and handling thicker materials.

Rotary die cutting machine:

Not like the roller die cutter cutting with steel rule die ,Rotary cutting equiped with rotating cylindrical die which mounted in fixed position.It can die cut small sheet ,especial for roll or web flexible material with large quantity.Here’s a more detailed explanation:

- Cylindrical Die: Utilizes a rotating cylindrical die with cutting edges engraved on its surface.

- Fixed Position: The die remains stationary while the material is fed through.

- Material Handling: Designed for continuous feeding of roll or web materials.

- Production Speed: Significantly faster than roller die cutters, excelling in high-volume production.

The rotary die cutting can work with Printing, perforating and laminating function same time if you need it.

Key Differences Summarized:

| Feature | Roller Die Cutter | Rotary Die Cutter |

|---|---|---|

| Cutting Mechanism | Flatbed with roller pressure | Rotating cylindrical die |

| Material Handling | Sheet materials | Roll materials |

| Production Speed | Slower | Faster |

| Applications | Short-run, prototyping, thicker materials | High-volume production, packaging, labels |

Choosing the Right Machine:The best choice for your specific needs depends on several factors:

- Production Volume: High-volume production favors rotary die cutters, while low-volume production is better suited for roller die cutters.

- Material Type: Roller die cutters can handle thicker materials, while rotary die cutters are ideal for thinner, flexible materials.

- Die Complexity: Roller die cutters offer more flexibility for intricate die designs.

- Automation Needs: Rotary die cutters can be integrated into automated production lines more easily.

In conclusion, both roller die cutters and rotary die cutters are valuable tools in the die-cutting industry, each with its own strengths and weaknesses. The optimal choice depends on factors such as production volume, material type, die complexity, and automation needs.By carefully considering these factors, businesses can select the most suitable die-cutting machine to meet their specific production requirements and achieve efficient, high-quality results.

What are the Advantages of Roller Die cutter?

Roller die cutter presses offer several advantages that make them a popular choice for various applications:

- Cost-Effective: The initial cost of a roller die cutter press and its cutting dies is generally lower compared to other types of die-cutting machines.

- Versatility: Capable of handling a wide range of materials, from thin paper to thick cardboard and plastic sheets.

- User-Friendly: Easy to operate and maintain, requiring minimal training.

- Low Maintenance: Simple mechanical design reduces the need for frequent maintenance and repairs.

- Environmentally Friendly: No hydraulic fluid is required, making it an eco-friendly option.

- Precise Cutting: Delivers accurate and consistent cuts, ensuring high-quality output.

- Customizable Dies: Compatible with various die types, including steel rule dies, to accommodate diverse cutting needs.

In conclusion, roller die cutter presses offer a compelling solution for businesses seeking a versatile, cost-effective, and user-friendly die-cutting machine. Their ability to handle a wide range of materials, coupled with their low maintenance requirements and ease of operation, make them a popular choice for various industries.

What are The Disadvantages of Roller Die Cutter ?

While roller die cutter presses offer many advantages, they also have some limitations:

- Lower Production Speed: Compared to high-speed rotary die cutters, roller die cutters operate at a slower pace, which can impact productivity for large-scale production runs.

- Larger Footprint: Roller die cutters tend to be larger and heavier than other types of die-cutting machines, requiring more floor space.

- Single-Function: They are primarily designed for die-cutting and cannot perform additional functions like perforating, printing, or laminating simultaneously.

- Manual Die Positioning: The cutting dies need to be manually positioned and aligned for each cutting cycle, which can be time-consuming and prone to human error.

In conclusion, while roller die cutter presses offer many advantages, it’s important to consider their limitations. While they are cost-effective, user-friendly, and versatile, they may not be the best choice for high-volume production or for applications requiring continuous feeding of materials.

What are Some Limitations Using a Roller Die Cutter Press?

While roller die cutter presses are highly efficient and versatile, there are several limitations and considerations to keep in mind:

1. Material Thickness:

- Limitations: Roller die cutters are typically designed for cutting relatively thin materials. Thicker materials can lead to slower cutting speeds, increased wear on the dies, and potential damage to the machine.

- Considerations: For thicker materials, consider using a Gerson other die cutting machine for example : Gerson beam press.

2. Die Complexity:

- Limitations: While roller die cutters can handle complex die designs, extremely intricate designs can be challenging to manufacture and maintain.

- Considerations: For very complex shapes, it might be more cost-effective to use a simpler die design or consider alternative cutting methods.

3. Material Type:

- Limitations: Some materials, such as very rigid or brittle materials, may not be suitable for roller die cutting.

- Considerations: Experimentation and careful die design can help to mitigate these issues.

4. Production Capactiry:

- Limitations: Roller die cutting press can not handle the material automatic ,especially for the roll material.

- Considerations: If for roll material ,we recommend to using other Gerson rotary die cutting mahcine .

5. Speed Limitations::

- Limitations:Although roller die cutters are generally fast, the speed can be limited by the material being cut and the complexity of the design.

- Considerations: For ultra-high-speed production, consider a Gerson high-speed die-cutting machine.

6. Safety:

- Considerations: Roller die cutters are powerful machines that can be dangerous if not used properly. It is important to follow safety guidelines and provide adequate training to operators.

Despite these limitations, roller die cutter presses remain a valuable tool for many industries. By understanding their capabilities and limitations, you can make informed decisions about their suitability for your specific production needs.

How to choose a Roller Die Cutter Press?

When you start to consider one roller die cutter press machine for your production ,The following item you must know it.

1.Material :The first thing that you need to know what material you need to die-cut from.Including material type ,dimension ,web or sheet etc.,You need to know from your material suppliers.

2.Finished part : The size of one cut, this determines the size of the cutting die.

3.Production Volume : How many quantities do you need to die cut per day or month?

4.Budget :How much money you are prepared to spend on the machine.

5.Space :You must know the space that can be used for the machine ,including putting material ,equipment etc.,The roller die cutter is not tabletop press ,although we have the small roller die cutter which can be placing on the table.

If you know all the above ,you could send the details to Gerson ,So we could give our model and size of roller die cutting machine in details .Then you could deside to buy or not.

Remember:Purchasing a new roller die cutter shouldn’t be a snap decision Although it is not expensive.

Do Gerson Have Roller Die Cutter in Stock for Sale ?

Gerson offers a unique approach to roller die cutter manufacturing. They primarily focus on producing machines tailored to specific customer requirements. While they may have some standard models in stock, it’s essential to contact them directly to confirm availability.

Custom vs. Stock:

- Custom Orders: Gerson can design and manufacture machines to meet your exact specifications, ensuring optimal performance for your specific needs.

- Stock Models: If a standard model meets your requirements, you can purchase it directly from stock, offering a quicker delivery time.

In Conclusion:If you’re considering a Gerson roller die cutter, it’s advisable to reach out to their team to discuss your specific needs. They can provide expert guidance and ensure that you get the right machine for your application, whether it’s a stock model or a custom solution.

What is the Price of Gerson Roller Die Cutter ?

Pricing for a roller die cutter press should consider several factors, including:

- Production Costs: This includes the cost of raw materials, labor, energy, and overhead expenses.

- Research and Development: The costs associated with designing and developing new models and technologies.

- Marketing and Sales: The expenses related to promoting and selling the machines.

- Profit Margin: A reasonable profit margin to ensure the sustainability of the business.

Gerson’s Commitment to Quality and Affordability

Gerson focus on quality and affordability is a testament to their commitment to customer satisfaction. By carefully managing costs and optimizing production processes, we are able to manufacture high-quality roller die cutter presses at competitive prices.If you’re considering purchasing a roller die cutter press, I encourage you to explore our offerings. Our dedication to customer satisfaction and their long history of manufacturing experience make them a reliable choice.