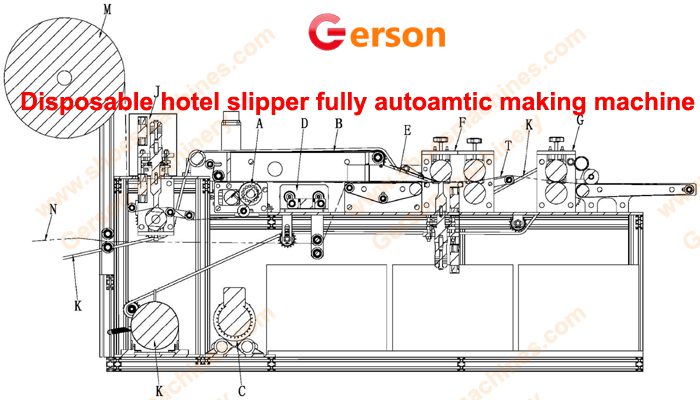

Disposable Hotel Slipper Fully Automatic Production Line

1.What is a Disposable Hotel Slipper Fully Automatic Production Line ?

Disposable hotel slippers automatic production line is also known as Disposable hotel slipper making machine which is Gerson’s patented product to improve customer’s production efficiency and solve the problem of labor cost. And the patented product invented by Gerson. It is a complete production equipment. All automatic, no need any manual operation in the middle. It only needs loading and final carton packing.

2.What kind of disposable hotel slippers can be produced?

The disposable hotel slippers making machine can be custom built based on your request. The normal machine can produce the below material :

Shoes Upper Material:

1.Terry; 2.Velour (aka Velvet); 3.Waffle; 4.Coral Fleece; 5.Micro suede; 6.Towel Fabric; 7.Super Soft Fabric; 8.Non-woven; 9.Pure EVA; 10.Short Floss; 11.Towel Fabric 12.Nap fabric

Sole Material:

1.EVA; 2.Anti-slip Cloth; 3.Sponge; 4.Foam; 5.TPR; 6.EVA covered EVA covered with synthetic leather for slipper.

3.How does a Disposable Hotel Slipper Fully Automatic Production Line Works ?(Video)

Cutting: The cutting device cuts the imported shoe upper fabric into individual shoe upper blanks;

Conveying: the suction conveying device will adsorb and convey the shoe upper blank output by the cutting device;

Forming:The shoe upper forming device cooperates with the suction conveying device to form creases and protrusions on the conveyed shoe upper blank.

Conveying : the sole blank and the upper blank forming the creases and protrusions are merged with the conveying device and conveyed by the conveying device.

Welding: the welding device welds the sole blank and upper blank sent by the conveyor to obtain the slipper blank.

Forming:The final forming device cutting slippers blanks into finished slippers.

4.What are the Advantages of a Disposable Hotel Slipper Fully Automatic Production Line ?

The advantage of this equipment is that the cut into individual shoe upper blanks are adsorbed and conveyed by the suction and conveying device, without axial pulling force on the shoe upper blanks. Therefore, the shoe upper blanks will not be caused to move along the axial direction of the shoe upper blanks. The blank is deformed. In addition, the shoe upper blank and the adsorption and conveying device are surface-to-surface coordination, and the shoe upper blank will not be deformed along the direction of the adsorption force. Therefore, the present invention ensures that the upper blank will not be deformed during the conveying process.

With the cooperation of the adsorption and conveying device and the shoe upper forming device, the shoe upper blank can be formed according to the design requirements. Therefore, after the formed shoe upper blank and the sole are welded, the quality of the slippers obtained can be guaranteed.

The speed of this product is very fast, the fastest can reach 120 per minute. Compared with the traditional die cutting machine and sewing machine, this kind of machine can complete the processing of one-time slippers at one time, and does not require multiple manual operations. It is continuously fast and saves labor and reduces costs.